Consult the manual that is supplied with the vehicle.

For further information email service@nooteboom.com

Consult the manual that is supplied with the vehicle.

For further information email service@nooteboom.com

Do you have a semi-trailer with or without manual steering?

With manual steering:

If you push the button “automatic central position” on your remote control the axles of the semi-trailer will automatically move into the straight-ahead position.

Hold down this button and drive your tractor straight ahead at walking pace and check in the mirrors to see whether the semi-trailer is following the tractor in a straight line.

When the combination is aligned you can release the button.

If you think the alignment is not yet 100% you can manually steer the axles of the semi-trailer to the left or to the right by briefly pushing the steer left or right button on your remote control.

Without manual steering:

Drive your tractor along at walking pace and steer to the left or right until the axles of the semi-trailer move into the straight-ahead position.

You can check whether the markings on the steering arm or on the axle assembly are aligned in relation to each other.

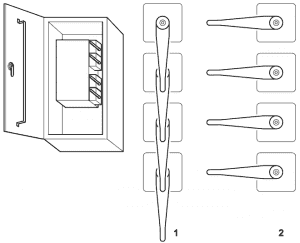

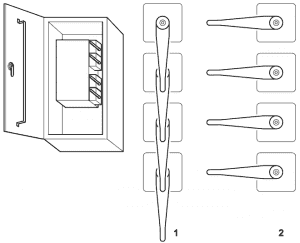

When the axles of the trailer are perfectly straight you can stop and open the 4 valves in the control box.

Now drive the tractor straight in front of the trailer, the axles of the semi-trailer will stay in the straight-ahead position.

When the tractor is straight in front of the semi-trailer you can put the 4 valves in the control box back into the drive position.

The combination is now aligned with each other.

1: position valves closed (driving position)

2: position valves open (aligning)

Drive your tractor along at walking pace and steer to the left or right until the axles of the semi-trailer move into the straight-ahead position.

Check whether the markings on the steering arm or on the axle assembly are aligned in relation to each other.

When the axles of the trailer are perfectly straight you can stop and open the 4 valves in the control box.

Now drive the tractor straight in front of the trailer, the axles of the semi-trailer will stay in the straight-ahead position.

When the tractor is straight in front of the semi-trailer you can put the 4 valves in the control box back into the drive position.

The combination is now aligned with each other.

1: position valves closed (driving position)

2: position valves open (aligning)

The electrical /hydraulic steering system is protected with various fuses.

They are located in the following places:

The hydraulic cylinders of the hydraulic steering system are equipped with air-bleed connections. These are easily accessible with extension hoses where necessary and quick-release couplings. Stickers with the colour of the circuit point out the location of these quick-release couplings of each separate circuit…

The following situations may occur:

The red light may come on for a few seconds when you steer the tractor to the left or right (e.g. when taking a bend).

After taking the bend and the tractor is back in the straight-ahead position, the light should automatically go off again. In this case no action is required.

If the light stays on there is not enough pre-pressure in the hydraulic steering system.

If your vehicle is equipped with manual steering you should use it to briefly steer left and right, then put it back in the automatic central position.

The red light will go off and now there is sufficient pre-pressure in the steering system.

Tip! This is best done during the coldest part of the day; if the temperature is rising the pressure in the hydraulic steering system will increase.

A blinking red light (situation 2) is always indicates the non-functioning of the manual steering and you must look for the solution of this malfunction in the electronics of the brake system or the cabling and/or connections between the ABS control unit and the ASA printed circuit board connection No. 23 (check electronics, cabling and electrical connections).

If the light is still blinking after the cabling has been checked we suggest you contact the Nooteboom service centre in Zwijndrecht or Wijchen to make an appointment in the workshop or to book a service mechanic.

Whether your semi-trailer is equipped with an emergency system depends on the year of manufacture and the ASA steering printed circuit version. If this printed circuit (grey connection box in picture below) has a white pushbutton your trailer will be equipped with an emergency system. In all other cases you will have to check in several places what causes the malfunction.

Whether your semi-trailer is equipped with an emergency system depends on the year of manufacture and the ASA steering printed circuit version. If this printed circuit (grey connection box in picture below) has a white pushbutton your trailer will be equipped with an emergency system. In all other cases you will have to check in several places what causes the malfunction.

The emergency system works as follows:

Push the white pushbutton, this will switch on the pump and at the same time, using the black valve buttons, move the control valve (mounted on the aluminium distributor block) completely up or down or from left to right (depending on the position of the control valve). This will activate the emergency system and you will be able to move the axles.

Please note:

The brakes must be released and driving forward or reversing with a loaded vehicle must be at low pace in order to keep the friction/resistance between the tyres and the road surface to a minimum.

If this doesn’t work we suggest you contact the department Aftersales or the service workshop in Wijchen or Zwijndrecht to make an appointment or to book a service mechanic.

Nooteboom Trailers has nearly all parts for your steering in stock.

You can order them by phone or email.

On our ‘parts catalogue’ website you can also select parts yourself and put them in your quotation folder.

When you have completed your quotation request we will contact you as soon as possible.